Arc pulsing involves four welding parameters; Peak current, background current, pulse width (duty cycle or percent – on – time), and pulse frequency (pulses per second). Although the parameters are most often chosen and changed according to the specific needs there are some industry standards that have been developed as starting parameters. Experimentation and experience will determine the final weld parameters chosen.

Arc pulsing involves four welding parameters; Peak current, background current, pulse width (duty cycle or percent – on – time), and pulse frequency (pulses per second). Although the parameters are most often chosen and changed according to the specific needs there are some industry standards that have been developed as starting parameters. Experimentation and experience will determine the final weld parameters chosen.

Step One : Average Current Required : Using the power supply in the unpulsed mode, establish the weld current required to melt and fuse the materials to be welded. Some times this weld current can be calculated using the 1 amp per 0.001” of material thickness rule. Example: If the material thickness or depth of weld penetration is 0.060 then 60 amps of average weld current will be required. Continue to increase the weld speed and current until a point where the arc and weld are still giving consistent results.

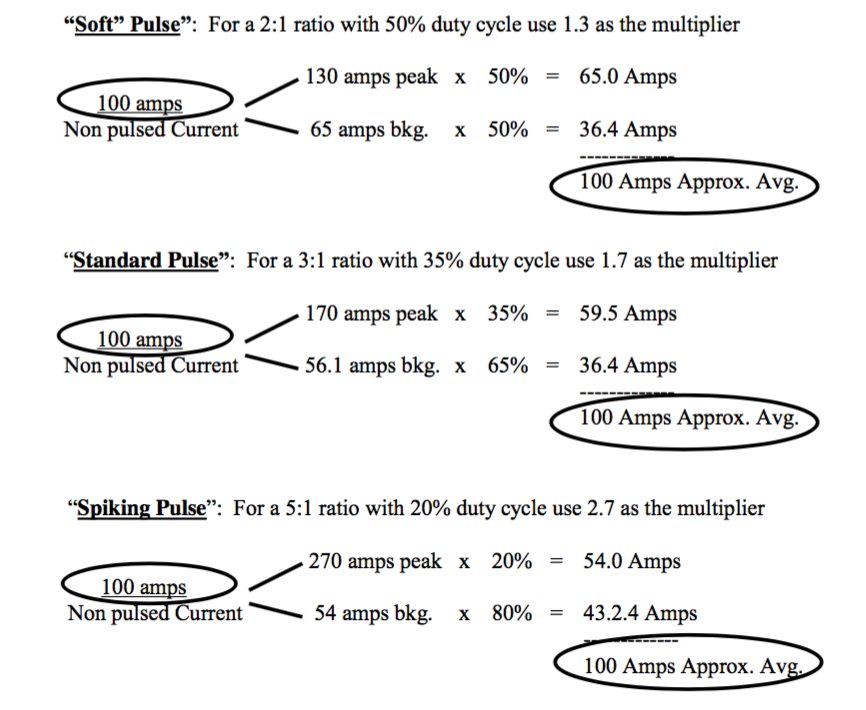

Step Two : Peak and Background Current Settings : The average current will be effected both by the peak to background current ratios and the duty cycle/pulse width (the percentage of time spent on the peak current setting) As before, these settings are changed according to the specific needs of the application. Peak to background current are normally in ratios of 2 – 5 and pulse widths are often 20% to 50%

If necessary a ballpark starting value can be pre – calculated using the following formula:

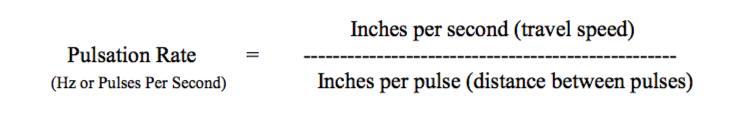

(Hz or Pulses Per Second) Inches per pulse (distance between pulses)

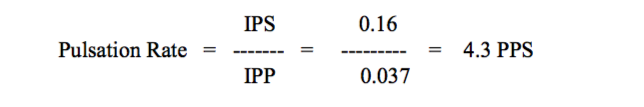

Example: Stainless steel material of thickness 0.060” being welded with a travel speed of 10 i nches per minute (0.16 inches per second) and a desired spot overlap of 75%. The weld puddle size will probably be 2.5 times the wall thickness (depending on any tooling used) so the distance between spot edges will be (2.5 x 0.06 x (1 – 0.75)) = 0.037

Many times, for thin wall or shallow penetration the starting pulsation rate will be half the travel speed in IPM. In the example above the travel speed was 10 IPM and the starting pulsation rate could be taken as 5 PPS

Varying the pulsation rate may also give a more stable arc for a given set of parameters and thus more consistent weld results. Experimentation and experience will determine the final weld parameters.

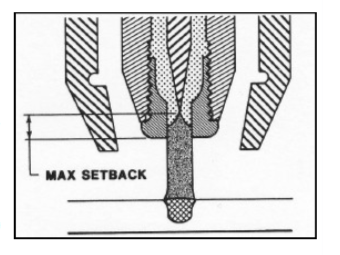

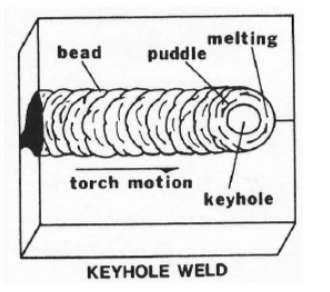

THIS TYPE OF WELD IS GENERALLY OBTAINED BY USING A STIFF. CONSTRICTED ARC. IN THE KEYHOLE MODE PENETRATION IS OBTAINED BY THE COMBINATION OF PLASMA AND GAS MOMENTUM WITH THERMAL CONDUCTION. WITH INCREASE PLASMA GAS FLOW RATED AND PLASMA SETBACK, A HOLE KNOWN AS THE KEYHOLE IS PIERCED THROUGH THE ENTIRE METAL THICKNESS AT THE LEADING EDGE OF THE WELD PUDDLE, WHERE THE FORCES OF THE PLASMA JET (COLUMN) DISPLACE TH E MOLTEN METAL. AS THE TORCH TRAVEL PROGRESSES AT A CONSISTENT SPEED, THE MOLTEN METAL, SUPPORTED BY THE SURFACE TENSION FLOWS BEHIND THE KEYHOLE TO FORM THE WELD BEAD.

THIS TYPE OF WELD IS GENERALLY OBTAINED BY USING A STIFF. CONSTRICTED ARC. IN THE KEYHOLE MODE PENETRATION IS OBTAINED BY THE COMBINATION OF PLASMA AND GAS MOMENTUM WITH THERMAL CONDUCTION. WITH INCREASE PLASMA GAS FLOW RATED AND PLASMA SETBACK, A HOLE KNOWN AS THE KEYHOLE IS PIERCED THROUGH THE ENTIRE METAL THICKNESS AT THE LEADING EDGE OF THE WELD PUDDLE, WHERE THE FORCES OF THE PLASMA JET (COLUMN) DISPLACE TH E MOLTEN METAL. AS THE TORCH TRAVEL PROGRESSES AT A CONSISTENT SPEED, THE MOLTEN METAL, SUPPORTED BY THE SURFACE TENSION FLOWS BEHIND THE KEYHOLE TO FORM THE WELD BEAD.

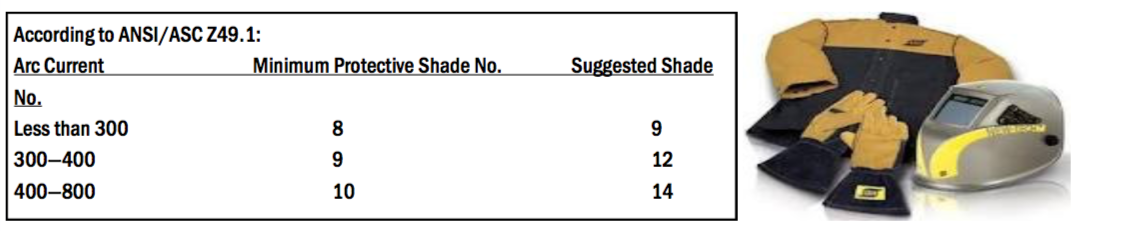

Eye injuries account for one – quarter of all welding injuries, making them by far the most common injury for welders. The best way to control eye injuries is also the most simple: proper selection and use of eye protection. Helmets alone do not offer enough protection. Welders should wear goggles or safety glasses with side shields that comply with ANSI Z87.1 under welding helmets and always wear goggles or other suitable eye protection when gas welding or oxygen cutting. To help in reducing eye injuries, you should educate workers about all of the dangers they face and should implement an eye protection plan that outlines proper welding behavior. Damage from ultraviolet light can occur very quickly. Normally absorbed in the cornea and lens of the eye, ultraviolet radiation (UVR) often causes arc eye or arc flash, a very painful but seldom permanent injury that is characterized by eye swelling, tearing, and pain. While most welding related eye injuries are reversible, with more than half of injured workers returning to work in less than two days and 95 percent in less than seven days, some eye injuries are irreversible and permanent visual impairment occurs. This is especially true with infrared and visible spectrum (bright light) radiation. Both can penetrate through to the retina and — although this is rare — can cause permanent retinal damage, including cataracts, diminished visual acuity, and higher sensitivity to light and glare.

Eye injuries account for one – quarter of all welding injuries, making them by far the most common injury for welders. The best way to control eye injuries is also the most simple: proper selection and use of eye protection. Helmets alone do not offer enough protection. Welders should wear goggles or safety glasses with side shields that comply with ANSI Z87.1 under welding helmets and always wear goggles or other suitable eye protection when gas welding or oxygen cutting. To help in reducing eye injuries, you should educate workers about all of the dangers they face and should implement an eye protection plan that outlines proper welding behavior. Damage from ultraviolet light can occur very quickly. Normally absorbed in the cornea and lens of the eye, ultraviolet radiation (UVR) often causes arc eye or arc flash, a very painful but seldom permanent injury that is characterized by eye swelling, tearing, and pain. While most welding related eye injuries are reversible, with more than half of injured workers returning to work in less than two days and 95 percent in less than seven days, some eye injuries are irreversible and permanent visual impairment occurs. This is especially true with infrared and visible spectrum (bright light) radiation. Both can penetrate through to the retina and — although this is rare — can cause permanent retinal damage, including cataracts, diminished visual acuity, and higher sensitivity to light and glare.

Welding fumes are very small particles that are formed when the vaporized metal rapidly condenses in air. They are typically too small to be seen by the naked eye but collectively form a visible plume. The health effects associated with metal fumes depend on the specific metals present in the fumes; they may range from short-term illnesses, such as metal fumes fever (i.e., flu-like symptoms), to long term lung damage and/ or neurological disorders. If the metal has been degreased with chlorinated solvent, other airborne gases (such as phosgene, hydrogen chloride, chlorine gas, etc.) maybe produced. These gases generally cause irritated eyes , nose and respiratory system, and symptoms may be delayed. Always read the Material Safety Data Sheets supplied with the material you are using. These MSDSs will provide information regarding the kind and amount of fumes as gases that may be dangerous to your health. Fume extraction is the best way to remove dangerous fumes from your welding environment. There are many fume extractors on the market to choose from.

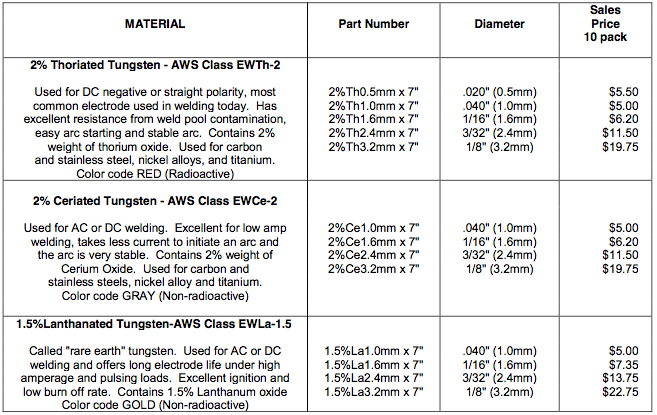

Welding fumes are very small particles that are formed when the vaporized metal rapidly condenses in air. They are typically too small to be seen by the naked eye but collectively form a visible plume. The health effects associated with metal fumes depend on the specific metals present in the fumes; they may range from short-term illnesses, such as metal fumes fever (i.e., flu-like symptoms), to long term lung damage and/ or neurological disorders. If the metal has been degreased with chlorinated solvent, other airborne gases (such as phosgene, hydrogen chloride, chlorine gas, etc.) maybe produced. These gases generally cause irritated eyes , nose and respiratory system, and symptoms may be delayed. Always read the Material Safety Data Sheets supplied with the material you are using. These MSDSs will provide information regarding the kind and amount of fumes as gases that may be dangerous to your health. Fume extraction is the best way to remove dangerous fumes from your welding environment. There are many fume extractors on the market to choose from. Welding Electrodes

Welding Electrodes

With international competition on the rise, how do you keep your customers coming back? In countries like China and India manufacturing exports continue to grow. These countries have implemented a new policy which emphasizes the development of domestic innovative capability. This has led to increased spending on R&D and a growing researcher base. Soon, not only will the part be available at a lower cost but at comparable quality as well. If developed countries are to remain competitive in the global economy, they will

With international competition on the rise, how do you keep your customers coming back? In countries like China and India manufacturing exports continue to grow. These countries have implemented a new policy which emphasizes the development of domestic innovative capability. This has led to increased spending on R&D and a growing researcher base. Soon, not only will the part be available at a lower cost but at comparable quality as well. If developed countries are to remain competitive in the global economy, they will  Decreased Variable Labor

Decreased Variable Labor Gas pressure regulators are used to reduce the pressure of gas supplied from a high-pressure cylinder of gas to a workable level that can be safely used for operating equipment and instruments. There are two basic types of gas pressure regulators: single-stage and two-stage. Single-stage pressure regulators reduce the cylinder pressure to the delivery or outlet pressure in one step.

Gas pressure regulators are used to reduce the pressure of gas supplied from a high-pressure cylinder of gas to a workable level that can be safely used for operating equipment and instruments. There are two basic types of gas pressure regulators: single-stage and two-stage. Single-stage pressure regulators reduce the cylinder pressure to the delivery or outlet pressure in one step.