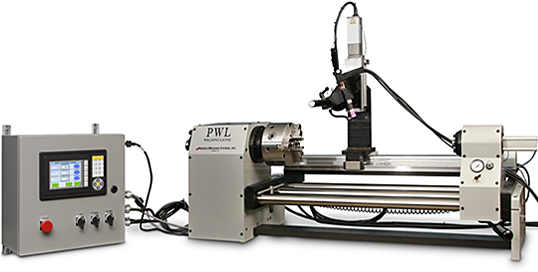

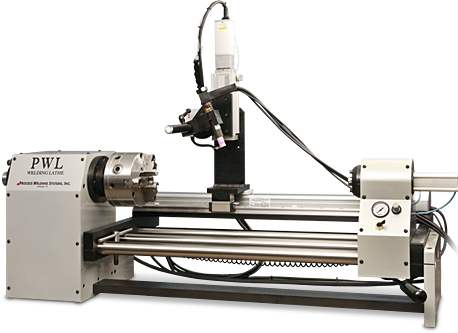

PWL-12-16 Standard Welding Lathe With CNC Control Panel: Specifically Designed for Welding a Wide Range of Circumferential Parts or Components for use in Both Plasma & TIG Welding Applications

The CNC control panel with color touch screen allows the operator to program the welding lathe movements with precision. The programmable axes are: X, Z and the torch angle around the Y axis. All axes are servo motor driven with for precise positioning capabilities. The X axis is 600mm long. See and OD Bellows example: CLICK HERE

In the automatic routine, this programmed list of positions is sequenced: First the axes are moved to position. Then the weld controller is started and the weld is made. When the weld is complete (gas post purge finished), the next position is moved to and another weld started.

When the automatic routine encounters a position of zero (0) in any of the programmed axes, this indicates that the last weld has been completed and the system returns to the load/unload position.

PWL-12-16 Standard Welding Lathe Specifications:

![]() Weight: 230 lbs.

Weight: 230 lbs.

![]() Weld Current Capacity: 300 amps

Weld Current Capacity: 300 amps

![]() Distance Between Centers: 24"

Distance Between Centers: 24"

![]() Maximum Diameter Part: 12.0"

Maximum Diameter Part: 12.0"

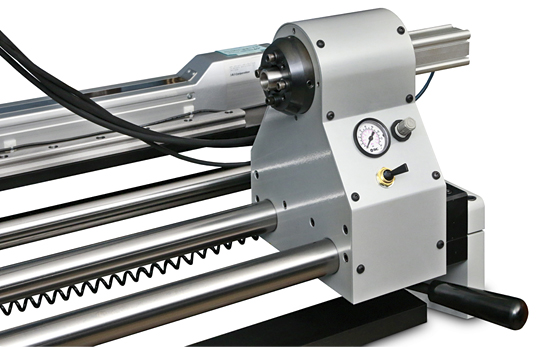

![]() Tail Stock Stroke: 3.0"

Tail Stock Stroke: 3.0"

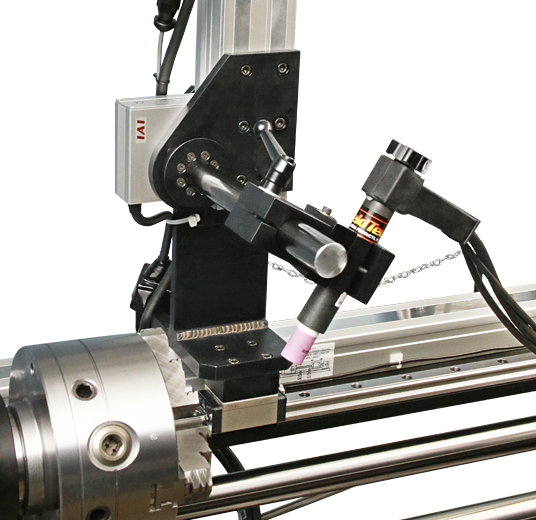

![]() Torch Stroke Weld / Retract: 4.0"

Torch Stroke Weld / Retract: 4.0"

![]() Lathe Bed: 1.5" diameter hardened rods

Lathe Bed: 1.5" diameter hardened rods

![]() Pneumatics: Equipped with speed controls

Pneumatics: Equipped with speed controls

![]() Tooling: 3 jaw 6.0" Set-Tru chuck & live center (Air or manual collet optional)

Tooling: 3 jaw 6.0" Set-Tru chuck & live center (Air or manual collet optional)

CNC CONTROL PANEL:

1. During the weld sequence, a screen displays the current position of the axes. When the weld sequence is complete, the system returns the axes to the load / unload position and the system is ready for another part.

1. During the weld sequence, a screen displays the current position of the axes. When the weld sequence is complete, the system returns the axes to the load / unload position and the system is ready for another part.

2. Programming features allow the positions for 20 different parts to be stored and recalled by means of the SELECT PART button. A screen is provided where the weld locations for the automatic weld sequence are programmed. Each list of positions will include X axis and Z axis positions in mm and angle position in degrees. Positions are set or modified by touching the screen on the number to adjust.

Pressing the TEST MOVE button will cause the axes to move to the programmed position. This can be helpful to verify the numbers entered. Pressing the TEST WELD AND MOVE button will cause the axes to move to programmed position, followed by initiating the weld schedule currently loaded. This can be used to perform single welds or repair welds as needed.

2. Programming features allow the positions for 20 different parts to be stored and recalled by means of the SELECT PART button. A screen is provided where the weld locations for the automatic weld sequence are programmed. Each list of positions will include X axis and Z axis positions in mm and angle position in degrees. Positions are set or modified by touching the screen on the number to adjust.

Pressing the TEST MOVE button will cause the axes to move to the programmed position. This can be helpful to verify the numbers entered. Pressing the TEST WELD AND MOVE button will cause the axes to move to programmed position, followed by initiating the weld schedule currently loaded. This can be used to perform single welds or repair welds as needed.

The system includes two servo slide actuators, and one servo rotary actuator. The X-axis slide is 600mm long and rigidly attached to the lathe rails. The 100mm Z-axis slide is attached to the x-axis slide. A 330 degree rotation rotary actuator is mounted upon the z-axis slide. The weld torch is mounted to the rotary actuator.

A 120V power input module with on/off switch is mounted on the side of the enclosure. A pendant with Start/Stop and E-Stop capability. Manual controls for the X, Y, and rotary axis located on the Touch screen enclosure.

The system includes two servo slide actuators, and one servo rotary actuator. The X-axis slide is 600mm long and rigidly attached to the lathe rails. The 100mm Z-axis slide is attached to the x-axis slide. A 330 degree rotation rotary actuator is mounted upon the z-axis slide. The weld torch is mounted to the rotary actuator.

A 120V power input module with on/off switch is mounted on the side of the enclosure. A pendant with Start/Stop and E-Stop capability. Manual controls for the X, Y, and rotary axis located on the Touch screen enclosure.