CORPORATE BACKGROUND:

Process Welding Systems was established in January 1993 as a manufacturer and distributor of precision automated welding systems. PWS owners have accumulated over 50 years experience in the welding industry with areas of expertise in applications engineering, design, electrical engineering, manufacture and installation of welding systems and technical support. In addition, our company has the commitment of and access to several experienced consultants to the welding industry in product development and systems design.

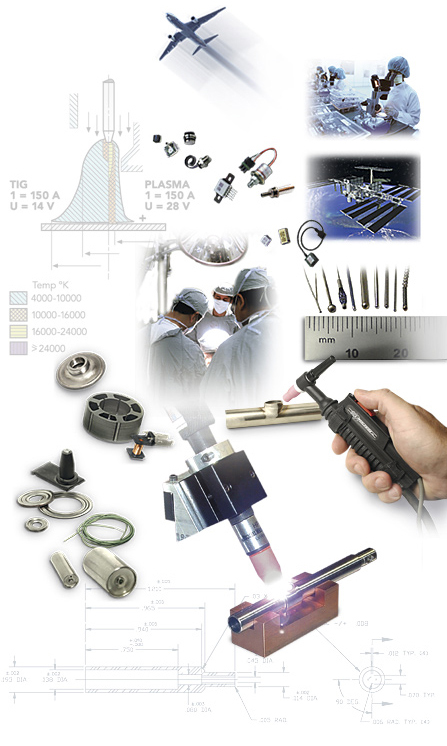

Our focus is selling Plasma and TIG welding systems (power supplies and related peripherals) to high tech welding facilities and manufacturers of precision components. The market for this equipment is niche oriented and the competition strong but extremely limited. To enhance the product offering, PWS is capable of designing custom welding systems and has designed and built a variety of accessories to automate in-place processes such as weld programmers, lathes, rotary positioners and custom torches.

To augment the sales focus of PWS, a complete weld lab is maintained for training, equipment demonstrations and weld development programs. Technical support is available for weld training, maintenance and equipment integration assistance. The company's skill in recommending solutions to complex welding applications is highly regarded by customers and competition.

BUSINESS PROFILE:

In 1993 Process Welding Systems began as the exclusive distributor for Oerlikon Welding Systems, a Swiss manufacturer of microplasma welding systems. The company developed an offering of accessories to this power supply such as a lathe and rotary positioner for part location. As the business grew, they continued to introduce new products that would enhance the initial product line and increase their sales potential with prospects having existing welding systems.

PWS has grown in sales volume through the efforts of in-house sales staff, associations with welding equipment distributors and manufacturer's representatives. Word of mouth and various components of the marketing mix such as direct mail, trade journal advertising and trade show participation have also played an important part in this success.

Sales are of a capital equipment nature and often take several months to consummate. In many situations, the sale goes beyond product presentation and proposal - sample welding, process assurance programs and leasing of equipment may be part of the process. In the case of a custom welding system - one of a unique design - there are numerous facets to the sale from conceptualization to sample welding to the final design and building of a system. In these situations, PWS often works as a supplier/consultant to a systems integrator who is providing the end user a complex production tool.

To maintain it's growth pattern PWS has developed a variety of products and many of the products we offer are of a "value added" nature. PWS is able to assist customers in improving their production processes through equipment to enhance or improve welding quality. These activities serve to broaden the product and services offering and make the company less dependent on outside sources for development. The acceptance of new equipment has been researched and appears to be welcomed consideration to the current customer base. Continual product development will ensure balanced growth and recognition as a source of expertise in welding equipment and processes.

A Sampling of PWS Equipment & Services Customers:

![]() General Electric Company

General Electric Company

![]() Smith & Nephew

Smith & Nephew

![]() Watlow Electric

Watlow Electric

![]() Aladdin Industries

Aladdin Industries

![]() Cordis, Inc.

Cordis, Inc.

![]() Power Conversions, Inc.

Power Conversions, Inc.

![]() John Crane Belfab

John Crane Belfab

![]() Rocketdyne

Rocketdyne

![]() Osram Sylvania

Osram Sylvania

![]() United Airlines

United Airlines

PWS Equipment Offering:

![]() Plasma & GTWA Welding Power Supplies

Plasma & GTWA Welding Power Supplies

![]() Lathes

Lathes

![]() Welding Controllers

Welding Controllers

![]() Motor Controls

Motor Controls

![]() Plasma Torches

Plasma Torches

![]() Micro Timers for Plasma Welding

Micro Timers for Plasma Welding