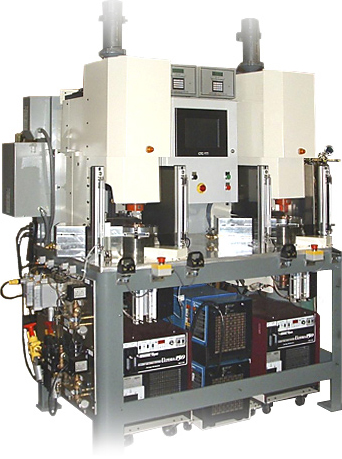

The system features two stations, and the operator manually loads one station and starts the welding sequence. While the station is welding the operator unloads/loads the other station and starts its welding sequence. The system will weld 1 valve every 30 seconds.

The system features two stations, and the operator manually loads one station and starts the welding sequence. While the station is welding the operator unloads/loads the other station and starts its welding sequence. The system will weld 1 valve every 30 seconds.

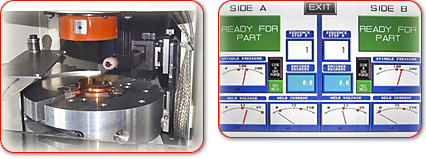

The system features two plasma welding systems controlled by the DT-100 Weld Programmer. Water cooled tooling was made in halves to open up and drop the part into the tooling. When the weld sequence is activated with dual palm buttons; the tooling closes and clamps the valve, the torch moves in to the welding position, a gas shield comes down to protect the part during welding, the part starts to rotate and the welding arc transfers to weld the valve.

The human interface (operator control) is a touch screen and displays views for machine set up, readouts of parameters and other machine functions. The complete system was designed and built by Process Welding Systems.