FEATURES:

FEATURES:

Traditional OD Bellows Welding lathes controlled by a welding operator are normally the refurbished remains of the infamous South Bend Lathe. The South Bend lathe and its application in the Bellows industry has entered into its sixth decade. See an ID Bellows Example: CLICK HERE

It’s mainstay is due to its superior alignment between the headstock and tailstock combined with the fact that the industry has not provided a low cost solution. In order for Bellows companies to overcome the South Bend lathe image problem; equipment manufacturers must conquer both cost and precision while accepting a lower margin of profit.

SYSTEM CAPABILITIES INCLUDE THE FOLLOWING:

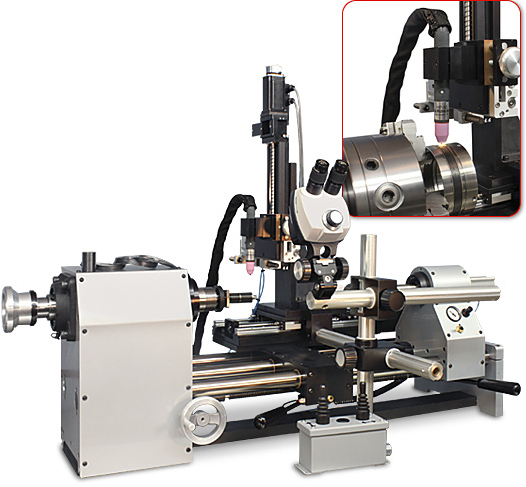

X- Major Axis: Maximum part length between Headstock to tailstock is 18″ with chuck; 23″ with collet closure.

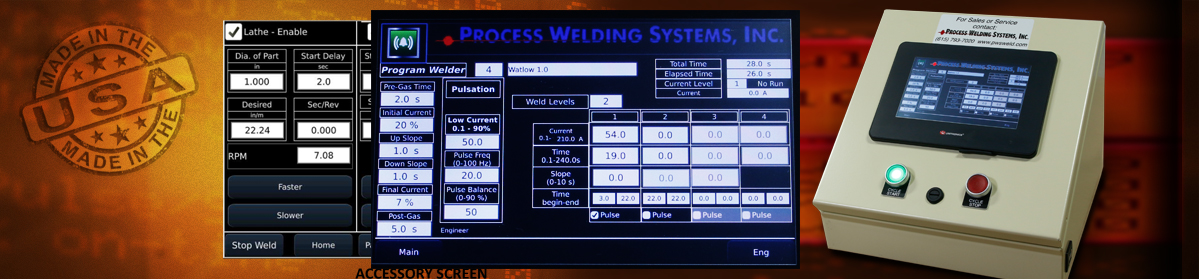

Manual Joy Stick Positioning: Stepper motor control of X-minor axis (left to right) and Z axis (up/down). Software accommodates changes in velocity that includes speed, acceleration and deceleration.

Stereo Microscope Leica Zoom (4): Body magnification of microscope .7x – 3x with 10x objectives provides 7x to 30x magnification; .5 exit lens provides a focal/focus point of 6.250″.