The PWS DT-400 is a four-channel weld process controller that replaces the PWS DT-100, and shares many of its attributes with many improvements.

The DT-400 has four fully isolated 0 – 10V analog outputs, ideal to control:

Arc Weld Current

Rotation or Linear Travel Speed Wire Feed Speed

Arc Voltage AVC, ALC

Each of these four channels are isolated from the control system and each other by means of a precision, wide bandwidth 3-port isolation amplifier. This ensures a channel’s pulsed output waveform to be crisp and accurate from 1Hz to 1kHz. A high degree of signal filtration exists on every I/O line and power input wiring as well. This filtration system keeps noise on the outside of the DT-400 main enclosure. Connection boxes attached to the outside of the DT- 400 main enclosure allow custom signal/wiring integration for different styles of weld power supplies, motor drivers, wire feeders, and AVCs. One connector is available to connect various DT-400 input functions to a remote pendant or for automation connections to a PLC or other controller system. All discrete I/O signals are optically

isolated for use with nominal 24V DC controls.

DT-400 Control for Plasma & TIG Welding

Welding and Manufacturing Greater Process Control.

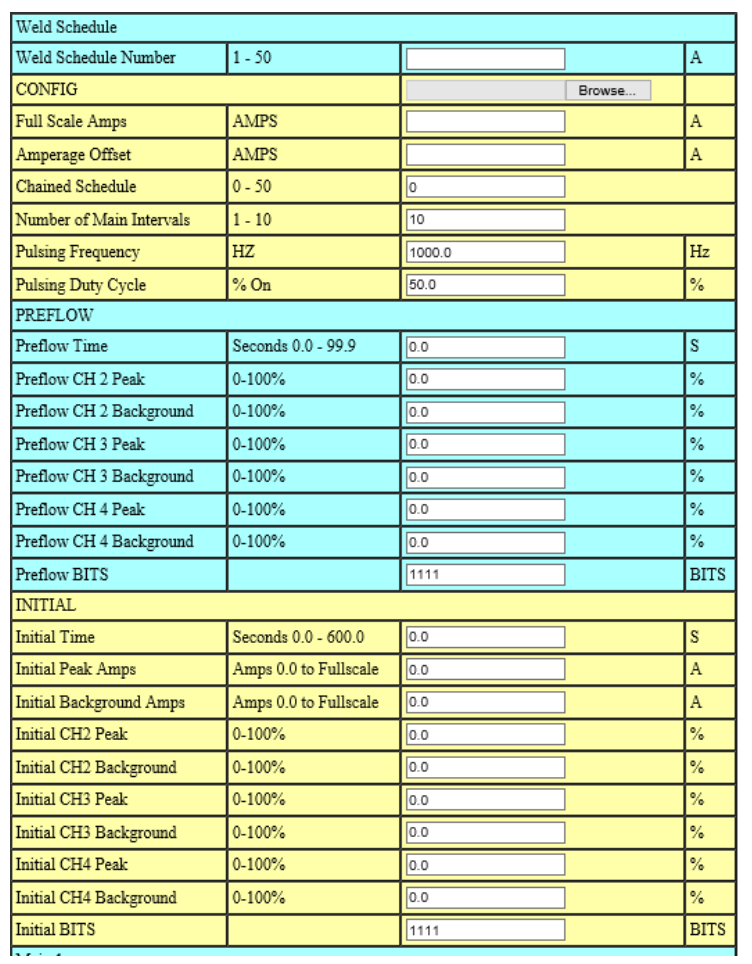

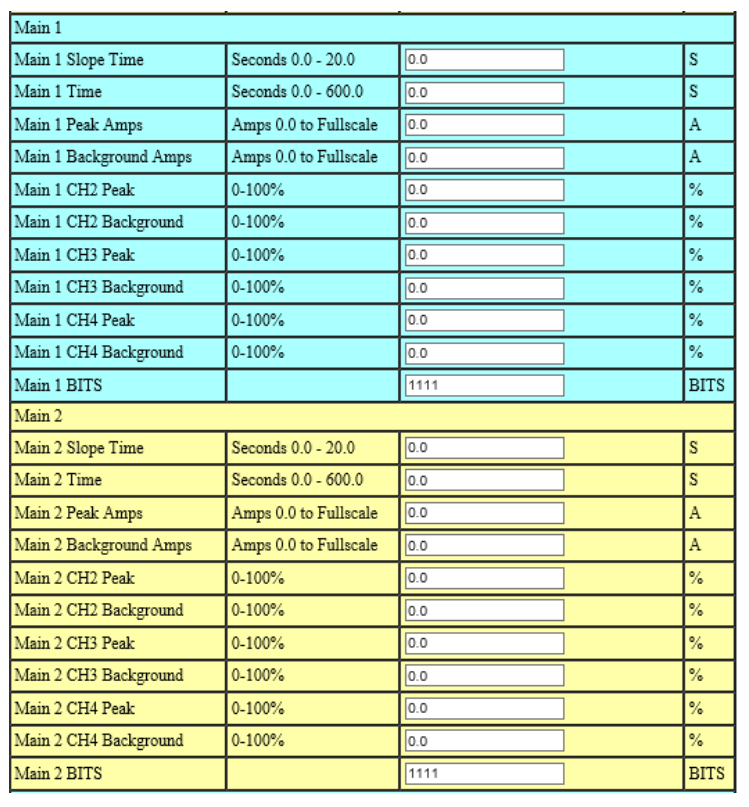

DT-400 Welding Schedule Data

With up to 10 main welding intervals with sloping from interval to interval.