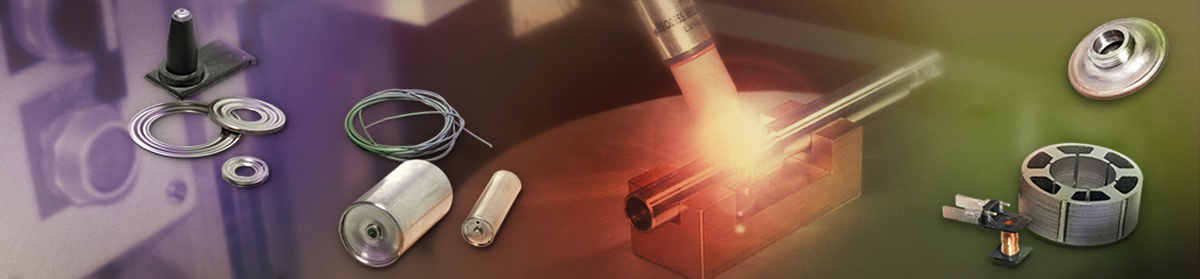

New Generation Semi-Automatic Custom Welding Lathe System

FEATURES:

Any and all improvements incorporated into Process Weldings first Bellows ID Welding system was predicated on our familiarity with existing designs used elsewhere. The mindset began with the question “What are the strengths and weaknesses of existing technology and how might they be improved.”

SYSTEM CAPABILITIES INCLUDE THE FOLLOWING:

Surface Flatness: A precision ground table top with an upper and lower clamping platform are manufactured as a precision assembly.

Alignment: The capacity to align upper and lower tooling nest within tenths of an inch i.e. .0005 or less addresses the most critical of applications.

Deflection: The system utilizes (3) diagonal rod supports for a stable clamping platform while providing easy access for the load/unload process.

Diaphragm Diameter Range: The Type (1) system accommodates a maximum diaphragm diameter of 5.095″.

Diaphragm Thickness: Tolerances specific to the existing design provides consistent/uniform heat sinking for materials as thin as .004″ in thickness.

Programmable Clamping Pressure: This feature results into a reduction of tooling wear with the elimination of repeated surface collisions between the upper and lower tooling surface; a trait common with most gravity type Die Shoes.

Programmable Clamping Speed: A feature designed as a time saver provides a high speed approach followed with a secondary seeking speed with the final application of force or pressure.

Programmable Torch Positioning: The torch has both a home position and a programmable position aka the welding position. At the end of each weld the torch may remain in place during load/unload or momentarily retract to its home position.

Electric Slide: Actuation of the electric slide moves the lower tooling nest upward and downward for accurate and repeatable positioning.

Man/Machine Interface: Software is currently available in both English and Chinese.

Welding Program Storage: DT-100 Programmer provides storage of 100 welding procedures.

Stereo Microscope Leica Zoom (4): Body magnification of microscope .7x – 3x with 10x objectives provides 7x to 30x magnification; .5 exit lens provides a focal/focus point of 6.250″.

High Purity Process Gas: A high purity gas filtration system designed to influence process yield is available for Plasma applications.