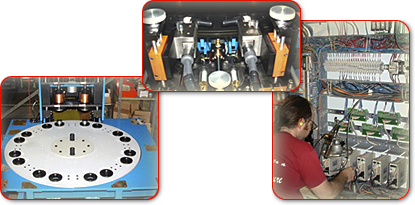

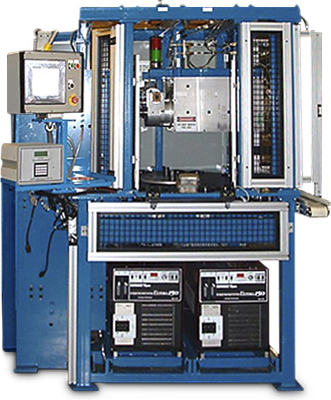

The system was built and designed to plasma weld two different sizes of valve assemblies. The machine operator would manually load two parts into the weld stations and activate dual palm buttons to start the weld sequence. The dial table would index and two plasma torches on the weld station would advance and weld the two parts. While the parts are being welding the operator would load two unwelded parts and start the sequence again. Approximate weld speed is 2 parts every 20 seconds.

The system was built and designed to plasma weld two different sizes of valve assemblies. The machine operator would manually load two parts into the weld stations and activate dual palm buttons to start the weld sequence. The dial table would index and two plasma torches on the weld station would advance and weld the two parts. While the parts are being welding the operator would load two unwelded parts and start the sequence again. Approximate weld speed is 2 parts every 20 seconds.

The parts are unloaded by a pick and place unit and dropped onto a conveyor that delivers the parts to a bin. The machine features upper and lower water cooled tooling, two plasma welding systems with DT-100 Weld Programmers and PLC sequencing. The complete turnkey system was designed and built by Process Welding Systems.