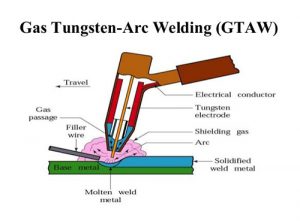

How Is a Welding Arc Established?

A sequence of events takes place between the electrode and the piece being welded. To strike the welding arc, a high frequency generator is used to provide a high voltage, low current superimposed on the welding current. The effect is a spark which creates a conductive path through the shielding gas

Welding Electrodes

Welding Electrodes

The electrode used in GTAW is made of tungsten or a tungsten alloy, because tungsten has the highest melting temperature among pure metals, at 3,422 °C (6,192 °F). As a result, the electrode is not consumed during welding, though some erosion (called burn-off) can occur. Electrodes can have either a clean finish or a ground finish—clean finish electrodes have been chemically cleaned, while ground finish electrodes have been ground to a uniform size and have a polished surface, making them optimal for heat conduction. The diameter of the electrode can vary between 0.5 and 6.4 millimetres (0.02 and 0.25 in), and their length can range from 75 to 610 millimetres (3.0 to 24 in).

Pure tungsten electrodes (classified as WP or EWP) are general purpose and low cost electrodes. They have poor heat resistance and electron emission. They find limited use in AC welding of e.g. magnesium and aluminum.

Cerium oxide (or ceria) as an alloying element improves arc stability and ease of starting while decreasing burn-off. Cerium addition is not

Using an alloy of lanthanum oxide (or lanthana) has a similar effect. Addition of 1% lanthanum has the same effect as 2% of cerium.

Thorium oxide (or thoria) alloy electrodes were designed for DC applications and can withstand somewhat higher temperatures while providing many of the benefits of other alloys. However, it is slightly radioactive. Inhalation of the thorium grinding dust during preparation of the electrode is hazardous to one’s health. Some electrode grinders have vacuum systems to prevent inhalation during grinding. As a replacement to thoriated electrodes, electrodes with larger concentrations of lanthanum oxide can be used. Larger additions than 0.6% do not have additional improving effect on arc starting, but they help with electron emission.

Higher percentage of thorium also makes tungsten more resistant to contamination.

Electrodes containing zirconium oxide (or zirconia) increase the current capacity while improving arc stability and starting and increasing electrode life. Zirconium-tungsten electrodes melt easier.

Ionized. A plasma exist during any arc occurrence. The energy level may vary enormously due to the ionization grade of the gas mixture. Essentially this spark allows the arc to be initiated

Were on the web www.pwsweld.com while the electrode and the work piece are separated.