WHAT IS KEYHOLE FUSION WELDING AND HOW CAN IT HELP YOU?

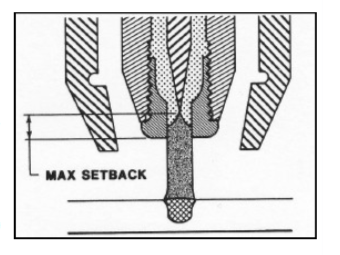

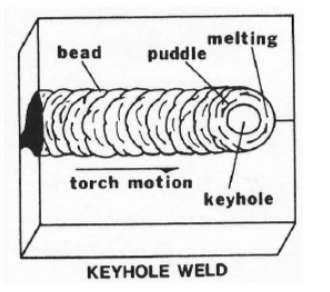

THIS TYPE OF WELD IS GENERALLY OBTAINED BY USING A STIFF. CONSTRICTED ARC. IN THE KEYHOLE MODE PENETRATION IS OBTAINED BY THE COMBINATION OF PLASMA AND GAS MOMENTUM WITH THERMAL CONDUCTION. WITH INCREASE PLASMA GAS FLOW RATED AND PLASMA SETBACK, A HOLE KNOWN AS THE KEYHOLE IS PIERCED THROUGH THE ENTIRE METAL THICKNESS AT THE LEADING EDGE OF THE WELD PUDDLE, WHERE THE FORCES OF THE PLASMA JET (COLUMN) DISPLACE TH E MOLTEN METAL. AS THE TORCH TRAVEL PROGRESSES AT A CONSISTENT SPEED, THE MOLTEN METAL, SUPPORTED BY THE SURFACE TENSION FLOWS BEHIND THE KEYHOLE TO FORM THE WELD BEAD.

THIS TYPE OF WELD IS GENERALLY OBTAINED BY USING A STIFF. CONSTRICTED ARC. IN THE KEYHOLE MODE PENETRATION IS OBTAINED BY THE COMBINATION OF PLASMA AND GAS MOMENTUM WITH THERMAL CONDUCTION. WITH INCREASE PLASMA GAS FLOW RATED AND PLASMA SETBACK, A HOLE KNOWN AS THE KEYHOLE IS PIERCED THROUGH THE ENTIRE METAL THICKNESS AT THE LEADING EDGE OF THE WELD PUDDLE, WHERE THE FORCES OF THE PLASMA JET (COLUMN) DISPLACE TH E MOLTEN METAL. AS THE TORCH TRAVEL PROGRESSES AT A CONSISTENT SPEED, THE MOLTEN METAL, SUPPORTED BY THE SURFACE TENSION FLOWS BEHIND THE KEYHOLE TO FORM THE WELD BEAD.

KEYHOLE WELDING IS ALMOST EXCLUSIVELY PERFORMED IN THE AUTOMATED MODE. TYPICALLY THIS TECHNIQUE IS USED FOR SQUARE BUTT WELDS ON MATERIAL THICKNESS FROM 0.093”(2.4 MM) TO 0.250” (6.4 MM) REQU IRING 100% PENETRATION IN A SINGLE PASS. MANUAL KEYHOLE WEL DING IS NOT RECOMMENDED BECAUSE OF DIFFICULTIES IN MAINTAINING CONSISTENT TRAVEL SPEEDS, TORCH POSITION, OR FILLER MATERIAL ADDITION.

ADVANTAGES:

1) REDUCED CURRENT LEVE LS

2) SINGLE PASS WELDS

3) MINIMIZED WELD PREPA RATION

4) NARROWER WELD BEADS

5) VISUAL PROOF OF 100% PENETRATION

6) LESS FILLER MATERIAL REQUIRED

___________________________________

DISADVANTAGES:

(1) LIMITED TO FLAT, HORIZONTAL, AND VERTICAL UP POSIT IONS

2) MORE SENSITIVE TO VARIABLE CHANGES

3) LIMITED TO AUTOMA TED OPERATIONS

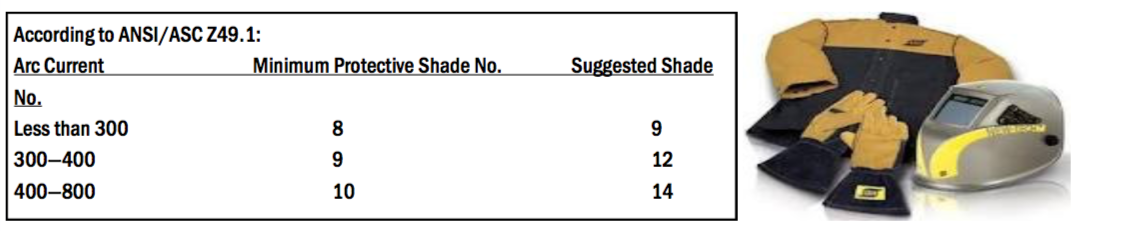

Eye injuries account for one – quarter of all welding injuries, making them by far the most common injury for welders. The best way to control eye injuries is also the most simple: proper selection and use of eye protection. Helmets alone do not offer enough protection. Welders should wear goggles or safety glasses with side shields that comply with ANSI Z87.1 under welding helmets and always wear goggles or other suitable eye protection when gas welding or oxygen cutting. To help in reducing eye injuries, you should educate workers about all of the dangers they face and should implement an eye protection plan that outlines proper welding behavior. Damage from ultraviolet light can occur very quickly. Normally absorbed in the cornea and lens of the eye, ultraviolet radiation (UVR) often causes arc eye or arc flash, a very painful but seldom permanent injury that is characterized by eye swelling, tearing, and pain. While most welding related eye injuries are reversible, with more than half of injured workers returning to work in less than two days and 95 percent in less than seven days, some eye injuries are irreversible and permanent visual impairment occurs. This is especially true with infrared and visible spectrum (bright light) radiation. Both can penetrate through to the retina and — although this is rare — can cause permanent retinal damage, including cataracts, diminished visual acuity, and higher sensitivity to light and glare.

Eye injuries account for one – quarter of all welding injuries, making them by far the most common injury for welders. The best way to control eye injuries is also the most simple: proper selection and use of eye protection. Helmets alone do not offer enough protection. Welders should wear goggles or safety glasses with side shields that comply with ANSI Z87.1 under welding helmets and always wear goggles or other suitable eye protection when gas welding or oxygen cutting. To help in reducing eye injuries, you should educate workers about all of the dangers they face and should implement an eye protection plan that outlines proper welding behavior. Damage from ultraviolet light can occur very quickly. Normally absorbed in the cornea and lens of the eye, ultraviolet radiation (UVR) often causes arc eye or arc flash, a very painful but seldom permanent injury that is characterized by eye swelling, tearing, and pain. While most welding related eye injuries are reversible, with more than half of injured workers returning to work in less than two days and 95 percent in less than seven days, some eye injuries are irreversible and permanent visual impairment occurs. This is especially true with infrared and visible spectrum (bright light) radiation. Both can penetrate through to the retina and — although this is rare — can cause permanent retinal damage, including cataracts, diminished visual acuity, and higher sensitivity to light and glare.

Welding fumes are very small particles that are formed when the vaporized metal rapidly condenses in air. They are typically too small to be seen by the naked eye but collectively form a visible plume. The health effects associated with metal fumes depend on the specific metals present in the fumes; they may range from short-term illnesses, such as metal fumes fever (i.e., flu-like symptoms), to long term lung damage and/ or neurological disorders. If the metal has been degreased with chlorinated solvent, other airborne gases (such as phosgene, hydrogen chloride, chlorine gas, etc.) maybe produced. These gases generally cause irritated eyes , nose and respiratory system, and symptoms may be delayed. Always read the Material Safety Data Sheets supplied with the material you are using. These MSDSs will provide information regarding the kind and amount of fumes as gases that may be dangerous to your health. Fume extraction is the best way to remove dangerous fumes from your welding environment. There are many fume extractors on the market to choose from.

Welding fumes are very small particles that are formed when the vaporized metal rapidly condenses in air. They are typically too small to be seen by the naked eye but collectively form a visible plume. The health effects associated with metal fumes depend on the specific metals present in the fumes; they may range from short-term illnesses, such as metal fumes fever (i.e., flu-like symptoms), to long term lung damage and/ or neurological disorders. If the metal has been degreased with chlorinated solvent, other airborne gases (such as phosgene, hydrogen chloride, chlorine gas, etc.) maybe produced. These gases generally cause irritated eyes , nose and respiratory system, and symptoms may be delayed. Always read the Material Safety Data Sheets supplied with the material you are using. These MSDSs will provide information regarding the kind and amount of fumes as gases that may be dangerous to your health. Fume extraction is the best way to remove dangerous fumes from your welding environment. There are many fume extractors on the market to choose from.