Our expertise, through the years, has been in PAW (Plasma Arc Welding) and GTAW (Gas Tungsten Arc Welding). It has been our experience that very clean gas in low amp plasma arc welding is very important.

As a result, we have written a procedure for welders, to help find some of the problems that can be caused by moisture and oxygen getting into the gas lines during welding. Please note the Attached Procedure “Check List for Contaminated Electrode, Dirty Weld Nozzles and Plasma Torch Care.”

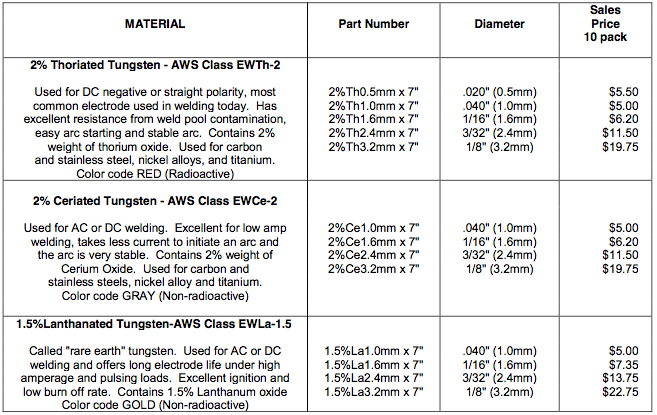

A wide variety of tungsten electrodes can be used during welding. Most welders prefer thoriated tungsten electrodes, but others like ceriated or lanthanated tungsten electrodes. It is difficult to determine which is best. The welder must consider his welding application, type of gas used, type of power supply, pulse rate, material being welded, etc. See the Attached Tungsten Sheet.

Please feel free to use the “Check List for Contaminated Electrode, Dirty Weld Nozzles and Plasma Torch Care” and the Tungsten Information Sheet. Pass them on to your welding engineers and welding technicians.

LOW AMP PLASMA WELDING

CHECK LIST FOR CONTAMINATED ELECTRODE, DIRTY WELD NOZZLES AND PLASMA TORCH CARE.

- A dark blue or black tungsten (Figure B) is a sign of moisture or oxygen getting into the plasma gas line (also called the pilot gas line). If the gas is good quality and the gas lines are leak free, the tungsten should remain a gray color (Figure A) not dark blue or black. Moisture and oxygen in the gas lines deteriorate the tungsten electrode, and thus the number of arc starts the tungsten electrode can produce is reduced. This cuts down on the number of arc starts in production and decreases production.

- Any leaks in the gas lines or fittings can allow air to be sucked into the gas system which adds oxygen and moisture to the welding gases being used. Levels of oxygen and water should be less than 5ppm. The most important gas in plasma welding is argon, which is used for the pilot gas (also called plasma gas). Argon being used should be at least 99.998% pure argon. In plasma welding, if the gas is not pure, it will contaminate the tungsten electrode and turn the tungsten electrode a dark blue and black color. If the problem is very severe, the discoloration will run all the way to the point of the tungsten electrode and clog the torch nozzle.

- To check for gas leaks, install a bottle of gas on the pilot gas line. It is recommended that the gas bottle be used with a dual stage regulator with a stainless steel diaphragm. Next, take a nozzle for the torch and solder the orifice of the nozzle closed. Clean the nozzle, after soldering, with acetone or alcohol, and install a small o-ring that will make a seal when the nozzle is screwed into the torch and hand tightened. Make sure that where the nozzle seats against the torch body is clean and free of dirt. If the nozzle does not seat well against the torch body, a gas leak can occur. Turn the pilot gas flowmeter up to its highest flow, and turn off the argon gas bottle. This willtrap gas between the tip of the torch nozzle and the argon gas bottle. Take a reading on the high pressure gas gauge of the gas regulator. Wait 15 to 30 minutes. If the gas system is leak free, the gauge reading will stay the same as when the gas bottle was turned off. If the gauge pressure drops, there is a gas leak in the system. The leak could be caused by a hole in the gas hoses or defective fittings and gaskets.

- If the system has a leak, check all fittings to make sure they are tight, and make sure that gaskets are sealing. You can also pinch the hose where the torch connects and trap gas from where the hose is pinched back to the regulator. If the leak stops, it is probably in the torch.

- Check for cracks in the torch body. If the torch has a back cap, check the o- ring on the cap and check the cap for holes or cracks.

- After it has been determined that the gas system is leak free, the system needs to be purged. Purging the gas lines will clean all of the moisture and oxygen out of the lines so that you will only have good clean gas in the system. Turn the pilot gas flow up to its highest flow rate, and let the gas run through the lines for at least 30 minutes to an hour. Next, start a pilot arc, and let it run at normal pilot arc gas settings (0.4 to 0.6 liters per minute) for 10 minutes. Turn off the pilot arc, and check to see if the color of the tungsten electrode is gray. If it is gray, the gas system is clean. If the color is black and blue, the system needs to purge longer to make sure it is clean.

- If your welding system is shut down over night, air with oxygen and moisture will get up inside the plasma torch. Before starting to weld on the next day, you need to again purge the gas lines approximately 5 to 10 minutes before starting to weld. You may want to turn the pilot gas down to a very low flow, such as 0.1 liters per minute, and let the gas run all night to keep the gas line clean. It will be such a low flow that it will not be of any economic importance.

- When the pilot arc is turned off, let the gas continue to flow for at least 10 to 15 seconds before turning off main power. The gas flow will keep the tungsten electrode from oxidizing until it cools down.

- Whenever thinking about electrode life, electrode contamination, ease of arc starting and arc stability, you should not forget that the exchange of ions takes place within the plasma column in both directions: from the electrode to the work piece and from the work piece to the electrode. If impurities such as lead, sulfur, aluminum, magnesium, copper, zinc, brass, oil, grease or any other dirty elements are on or in the material being welded, they will contaminate the tungsten electrode and nozzle. You then cannot count on the maximum number of welds before replacing the tungsten electrode and weld nozzle.

- Clean the nozzle orifice with acetone or alcohol and a Q-tip. A round wooden toothpick can be used to clean the orifice of the nozzle. Weld nozzles trap contamination during welding and will need to be cleaned every time the tungsten is re-ground.

- The pilot arc should be bright white with a light blue tint. If the color changes to orange or purple that is a sign of contamination. The pilot arc may draw back into the nozzle, which is a sign that the tungsten electrode has deteriorated.

- WARNING: It is extremely important, when tightening the nozzle onto the torch head, that you do not over tighten the nozzle and strip the threads. Copper is a very soft material which makes it easier to over tighten the nozzle. Tighten the nozzle until it barely makes intimate contact with the end of the torch head. It is recommended that pliers be used to tighten the nozzle. Be careful not to grab the torch head with the pliers. Be careful not to cross thread the nozzle. If the nozzle is cross threaded it will damage the threads inside the torch head. Do not get dirt, grease or oil inside the torch head or on the nozzle threads. This will damage the threads in the torch head. If the torch head is damaged by the pliers, it can cause a gas leak between the nozzle and torch head and the nozzle will not seat properly against the water cooled part of the torch head. If the threads are stripped, and the torch head is damaged, the torch will have to be replaced. Periodically clean the inside of the torch and threads where the nozzle seats with alcohol or acetone. Make sure that technician’s hands are clean when servicing torches. Dirt, oil, grease and grit are not acceptable on any of the torch parts. The plasma welding torch is an expensive device and should be handled with great care.

- The type of hose material that the pilot gas and shield gas are passed through is very important. All plastics can have moisture and oxygen that diffuse through the walls of the hose material. When welding sensitive materials such as titanium the welding system may need to be plumbed with stainless steel gas lines.

TUNGSTEN ELECTRODE PRICES

There is no way to tell a welder which tungsten is best for his application. Welders use different power supplies with different types of arc starters. Each welding application uses different gases and electrode tip configurations. Also, the material being welded will vary. Other factors such as weld speed, pulsing, number of arc starts and how the tungsten is sharpened will affect tungsten life. It is recommended that you test the tungsten before putting it into production. Ask us for a free sample tungsten electrode to conduct your own test.