Where we Stand Now.

With international competition on the rise, how do you keep your customers coming back? In countries like China and India manufacturing exports continue to grow. These countries have implemented a new policy which emphasizes the development of domestic innovative capability. This has led to increased spending on R&D and a growing researcher base. Soon, not only will the part be available at a lower cost but at comparable quality as well. If developed countries are to remain competitive in the global economy, they will have to rely more on technology. Investment in technology is therefore a crucial factor for sustained economic health. A continuous process of change, innovation and productivity will allow you to be competitive as the global market continues to evolve. Innovate, or lose.

With international competition on the rise, how do you keep your customers coming back? In countries like China and India manufacturing exports continue to grow. These countries have implemented a new policy which emphasizes the development of domestic innovative capability. This has led to increased spending on R&D and a growing researcher base. Soon, not only will the part be available at a lower cost but at comparable quality as well. If developed countries are to remain competitive in the global economy, they will have to rely more on technology. Investment in technology is therefore a crucial factor for sustained economic health. A continuous process of change, innovation and productivity will allow you to be competitive as the global market continues to evolve. Innovate, or lose.

Whoever makes things better, cheaper, faster wins!

America must continue to be the leader.

STAYING COMPETITIVE

In order to compete with countries like China and India we need to adopt equipment and technology that will lower production cost while enhancing the product quality at the same time. Companies must now

look for new and innovative ways to improve their processes, their workers productivity, and, ultimately, their overall equipment effective- ness.

________________________________________________________________

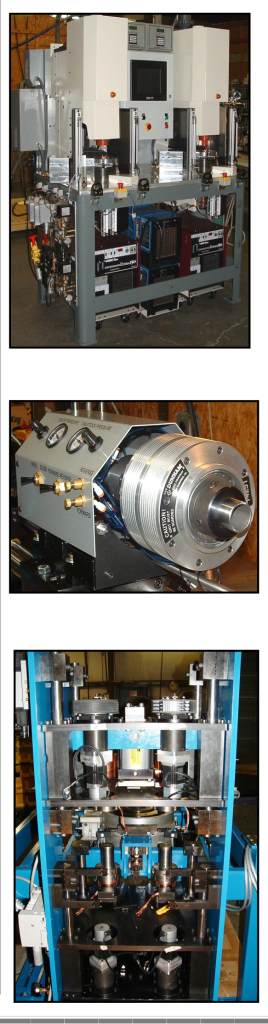

LET PROCESS WELDING SYSTEMS HELP

BENEFITS OF AUTOMATED WELDING

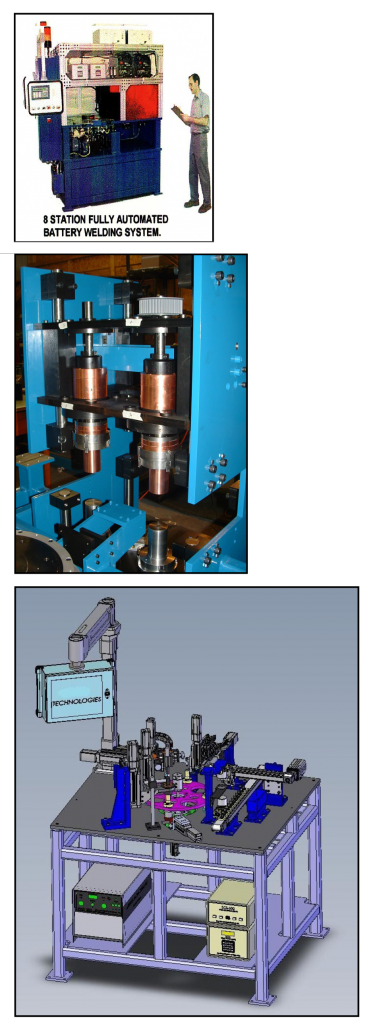

With quality and productivity as buzzwords, and customers demanding superior products, implementing an automated welding system may determine whether a company remains competitive. Automating your welding production offer three main advantages: decreased variable labor costs, improved weld quality, and decreased scrap.

Decreased Variable Labor

Decreased Variable Labor

ImprovedWeld Quality:

Mechanized welding improves weld integrity and repeatability. Humans tend to “smooth over” a mistake with the torch, hiding lack of penetration or a possible flawed weld.

Decreased Scrap/Rework:

It’s never good to throw away parts with accumulated significant value because of a welders lack of detail. Automating weld parameters and part placement decreased the error potential.

Costs: Amachinecontrolledsys- tem always repeats the same welding parameters. Reliance on human welders dramatically in- creases a manufacturer’s labor costs. A fully automatic system with sufficient stations can run at four or at eight times the pace of a skilled welder.

|

A fully automatic system with sufficient stations can run at four or at eight times the pace of a skilled welder. |

||

SOME OF OUR CUSTOMERS

- General Atomics

- Teledyne Energy

- McKenna Machine

- Delphi Automotive

- Fuel Cell Energy Corp.

Angio-Dynamics

Pratt & Whitney

Parker Hannifin Corp. Lake Region

Draper Laboratory