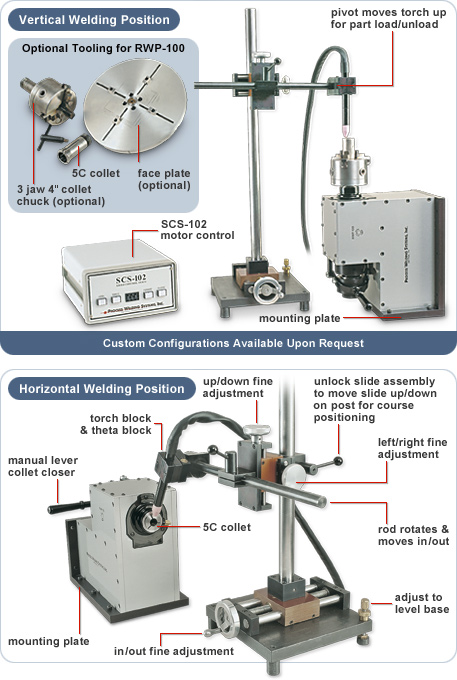

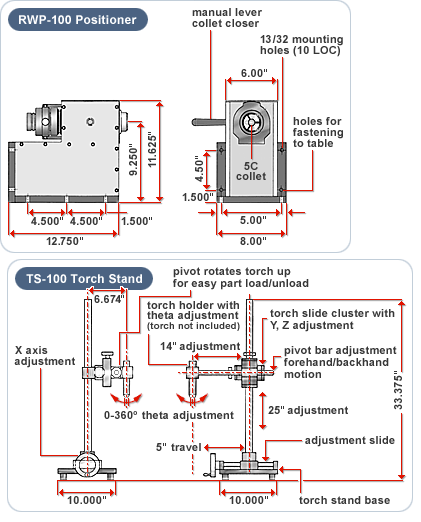

Weld Engineering has recently directed manufacturing engineering to adopt weld standardization into the production work cell. Weld standardization is a consistent and uniform approach to a given welding application. Standardization is divided into two critical components that include Process and Producibility. It is important to recognize that process control should remain independent of the theoretical approach utilized for a given welding application. The first step is to clone every element of each workstation in order to achieve the same process identity throughout production. The second component of standardization is Producibility. Producibility is simply the pursuit of a weld applications procedural limit. With each material there exists a weldability range in which a satisfactory weld can be produced. The candidate material or application is welded at a variety of speeds and parameters. Observations are documented as the window of Producibility is pushed to its maximum limit. This continues until some aspect of acceptance criteria is no longer satisfied. It is at this point that the low, middle, and upper control limits of the process are established. Standardization substantiates a company’s commitment to further product quality and establishes a basis for comparing quantity and quality. Qualification by similarity is one of the many benefits of standardization. Process Welding Systems Welding Positioner's are second to none. Call us today and ask about them and how best to improve the quality of your product production.