Announcing the sale of high quality, low cost tungsten electrodes for GTAW and PAW welding. Thoriated, ceriated and lanthanated electrodes are in stock.

Both TIG and Plasma processes require tungsten electrodes to generate the arc for welding. For most applications, 2% Thoriated tungsten has been used as the general purpose electrode material. With this electrode almost all materials can be welded including aluminum.

Over the past few years, several other tungsten electrode types have been formulated that offer specific advantages for certain applications. Cerium has replaced Thorium for a tungsten alloy that offers great arc starting performance with no radioactivity like thorium. Lanthanum has also been added to improve arc starting and offers better performance for certain applications.

Here is a quick reference table with the advantages of each tungsten type;

2% Thoriated Tungsten (color Red)

- The standard for most applications, but is slightly radioactive. Works well for DC welding and can be used for AC welding on aluminum for non-critical applications. Has some tendency to split if used for aluminum and the electrode is contaminated.

- Medium to good wear rates and low current arc starting capabilities

- Good general purpose electrode

2% Ceriated Tungsten (color Grey)

- Electrode is not radioactive and offers excellent DC welding capabilities. Can also be used for AC welding of aluminum.

- Excellent low wear rates and excellent low current DC capabilities

- Excellent arc starting properties

2% Lanthanated Tungsten (color Blue)

- Electrode is non radioactive and offers excellent DC and AC welding capabilities. Can be used for AC welding of aluminum.

- Excellent low wear rates and excellent low current DC capabilities

- Excellent arc starting properties

The proper choice of electrode type can improve welding processes by offering improvements in arc starting and offering longer life between re-sharpening. For very low current applications, the Ceriated and Lanthanated Tungsten Electrode materials can give much better performance.

Our Electrodes are ready for purchase over the internet or by purchase order. Discounts are available on orders of 10 or more boxes. The tungsten electrodes are 7” long and diameter sizes from 0.020 up to 1/8”. Visa, Mastercard and American Express orders are accepted. Contact us for pricing, technical information or free tungsten electrode samples.

Our Electrodes are ready for purchase over the internet or by purchase order. Discounts are available on orders of 10 or more boxes. The tungsten electrodes are 7” long and diameter sizes from 0.020 up to 1/8”. Visa, Mastercard and American Express orders are accepted. Contact us for pricing, technical information or free tungsten electrode samples.

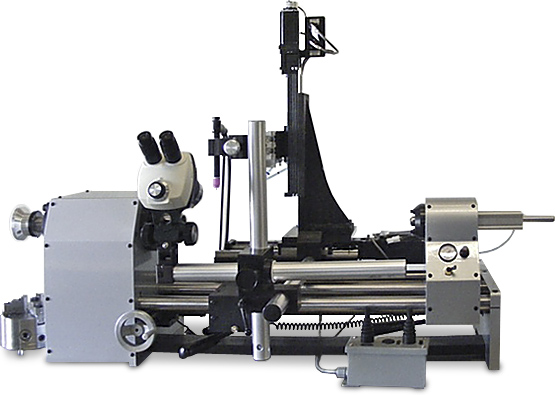

Process Welding Systems also offers Plasma and Tig welding power supplies, weld programmers, plasma welding torches, welding lathes and positioning devices. Custom automation systems, custom welding systems are designed and built to meet demanding customer specifications with accuracy and consistent weld quality results. Complimentary sample welding and weld development assistance are standard services.

For further information call or write: Process Welding Systems Inc., 72 Buchanan St., LaVergna, TN 37086. Phone: 615-793-7020, Fax: 615-793-7557, Email: sales@processwelding.com www.processwelding.com