We are always interested in our customer’s welding product needs. To maintain it’s growth pattern PWS has developed a variety of products and many of the products we offer are of a “value added” nature. PWS is able to assist customers in improving their production processes through equipment to enhance or improve welding quality.

We are always interested in our customer’s welding product needs. To maintain it’s growth pattern PWS has developed a variety of products and many of the products we offer are of a “value added” nature. PWS is able to assist customers in improving their production processes through equipment to enhance or improve welding quality.

These activities serve to broaden the product and services offering and make the company less dependent on outside sources for development. The acceptance of new equipment has been researched and appears to be welcomed consideration to the current customer base. Continual product development will ensure balanced growth and recognition as a source of expertise in welding equipment and processes.

SERVICES INCLUDE:

![]() Design services for precision welding systems (manual load/unload or semi-automatic)

Design services for precision welding systems (manual load/unload or semi-automatic)

![]() Integration of welding system accessories & site installation assistance

Integration of welding system accessories & site installation assistance

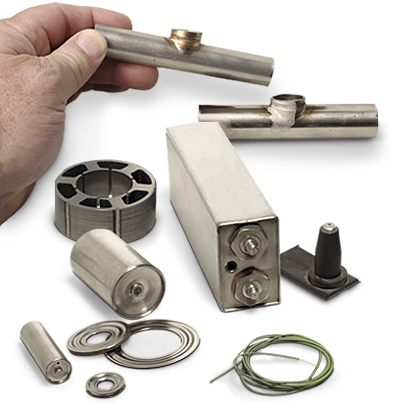

![]() Experienced staff for custom design & manufacture of tooling, fixtures & specialty torch nozzles

Experienced staff for custom design & manufacture of tooling, fixtures & specialty torch nozzles

![]() Free weld application review & process recommendation

Free weld application review & process recommendation

TECHNICAL SUPPORT:

![]() Troubleshooting, maintenance & repair of equipment

Troubleshooting, maintenance & repair of equipment

![]() Weld training – skills development

Weld training – skills development

![]() Weld development – material evaluation, joint design, weld parameter development

Weld development – material evaluation, joint design, weld parameter development

![]() Comprehensive consumable inventory stock of replacement parts for plasma power supplies, accessories & plasma welding torches

Comprehensive consumable inventory stock of replacement parts for plasma power supplies, accessories & plasma welding torches

CUSTOM PRODUCTS AND ACCESSORIES:

![]() Special gas shields – MIG, TIG & Plasma

Special gas shields – MIG, TIG & Plasma

![]() Torch slides – X, Y, Z

Torch slides – X, Y, Z

TIG Welding – Beginners Guide

TIG Welding – Beginners Guide – Gas

Now you may think talking about gas before the welder is odd, but bear in mind that if you are on a budget then the gas is going to represent a significant outlay.

Unlike MIG welding TIG welding can only use pure argon (or other specialist gases), so using food grade CO2 for example is not possible.

TIG Welding – Beginners Guide – Welders

Make sure that the welder actually comes with a proper TIG torch, as some Arc Welders can be used for TIG welding but do not come supplied with a TIG torch as pictured below.

|

| A TIG Torch |

TIG Welding – Beginners Guide – The Tungsten

The tungsten is the electrode that sticks out of the front of the torch. Confusingly there are various different types, that are better suited to different applications. Your welder may come supplied (as mine did) with an unsuitable tungsten electrode. Most people suggest a 2% thoriated tungsten, but this is radioactive, so perhaps go for a 1-2% lanthanated electrode which I believe performs similarly.

You should sharpen your tungsten before first use.

OK so hopefully that covers the gear now a little on technique.

TIG Welding – Beginners Guide – Holding the Tig Torch

To avoid damaging the electrode, you will need to hold it around 2 – 3mm from the working surface. With a welding mask on this is no mean feat, and will take a great deal of practice to get the hang of. The torch should be held in a way that is very comfortable;

|

| Index Finger on Top |

|

| Or like a pencil |

Gloves should be used or you will get sun burn from the UV radiation emitted from the arc. If you are working on a large item, it may heat up meaning you will need something heat proof to rest your hand on.

The torch should be held with the electrode as upright as possible, whilst still allowing you to see what you are doing.

TIG Welding – Beginners Guide – Setting the Amperage

On the most basic of TIG welders there will be an amperage control, too little amperage and you will not melt the metal, too much and you make a hole.

The better the conductivity of the metal the higher your amperage will have to be, aluminum requires a higher amperage that steel for the same thickness.

TIG Welding – Beginners Guide -Gas Flow Rate

During welding set gas flow around 7 – 8 liters per minute.

PROCESS WELDING SYSTEMS AUTOMATED WELDING SYSTEMS TAKE YOU TO THE NEXT LEVEL:

Our automated system helps you increase welding quality, improve welding productivity, enhance the working environment and decrease manufacturing cost.

Special Purpose Machines (SPM) with simple timer and contractor control to complex designs using CNC controllers, servo motors, pneumatics, hydraulics as requirement.

Process Welding Systems’ design, manufacture and sell complete weld automation stations for mass production with automated welding of various components , equipments, overlay metal build up, hard-facing and metal spray applications .

See our CUSTOM AUTOMATED LATHE